Best 3-Point Hitch Log Splitters

- April 17, 2024

- 0 comment

If you’re on the hunt for a reliable and efficient way to split logs for firewood, a 3-point hitch log splitter might just be your best friend. These powerful machines connect to your tractor, turning a tough job into a walk in the park. Whether you’re a farmer, a homesteader, or someone who loves a cozy fireplace, these splitters are designed to make your life easier. In this article, we’ll explore the top 3-point hitch log splitters on the market. From their robust power to their clever features, we’ve got all the details to help you choose the perfect partner for your log splitting needs. Let’s dive in and find out which log splitter is the champion of chopping!

List of the Best 3 PT log splitter:

- Ruggedsplit 322-24-TR 22-Ton 3-Point Log Splitter

- Boss 35 Ton H/V 3-Point Hitch Log Splitter

- Split-Fire 3403 3 Point Hitch Log Splitter

- Rock Venom 25-Ton 3-Point Log Splitter

What is 3 Point Hitch Log Splitter?

A 3-Point Hitch Log Splitter is a powerful attachment designed for seamlessly splitting logs, harnessing the strength and mechanics of a tractor. This robust tool attaches efficiently to a tractor’s three-point hitch system, utilizing the tractor’s hydraulic power for formidable and consistent performance. Perfect for farmers and property owners needing to process substantial amounts of firewood, this attachment offers the durability, high power, and convenience of integrating with existing farm machinery, making it an invaluable asset for efficient wood processing.

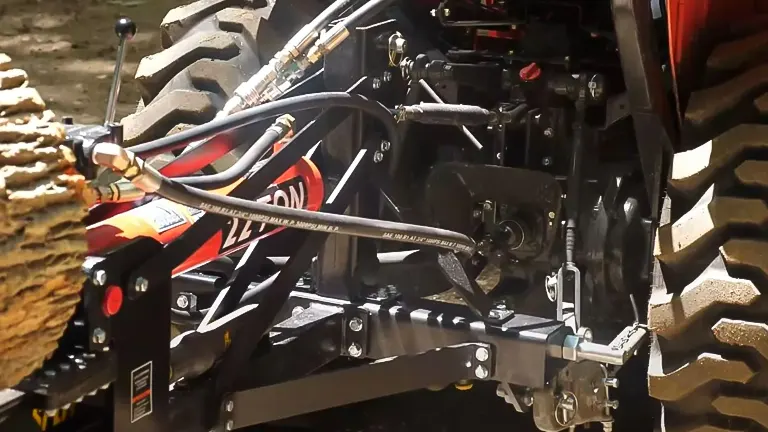

1. Ruggedsplit 322-24-TR 22-Ton 3-Point Log Splitter

Specifications

- Ram Force: 22-Ton

- Stroke: 24″

- Hitch Compatibility: Category 1 or 2, 3-point hitch

- Blades: 2-way and 4-way (slip-on)

- Hoses: Two high-pressure (1/2″ and 3/4″), tractor connection adapters not included

- Warranty: 1-year parts

The Ruggedmade RuggedSplit 322-24-TR is a formidable player in the world of log splitting, designed to marry seamlessly with the 3-point hitch system of most compact agricultural tractors. This robust machine is a part of the RS 300 Series and stands out for its sheer power and efficiency.

This horizontal log splitter is engineered to connect to either Category 1 or Category 2 3-point hitches, making it highly versatile for various tractor models. With a substantial 22-ton ram force and a 24″ cylinder stroke, this splitter is built to handle sizeable splitting tasks with ease. The inclusion of both a 2-way blade and a slip-on 4-way blade elevates its functionality, allowing users to tackle different splitting needs effectively.

Pros

- With a 22-ton ram force, it delivers exceptional splitting power for various types of wood.

- The inclusion of both 2-way and slip-on 4-way blades provides flexibility, allowing users to adapt the splitter based on the size and type of logs.

- Designed to attach to both Category 1 and Category 2 3-point hitches, it offers broad compatibility with compact agricultural tractors.

- The push-through design ensures split wood is neatly managed, either falling onto a conveyor or a catcher tray.

- Features like the adjustable beam working height and the auto-return hydraulic control valve enhance user comfort and efficiency.

Cons

- Requires connection to a tractor’s hydraulic system, which might not be ideal for users looking for a standalone unit.

- The exclusion of agricultural quick-connectors and adapters means additional purchases and setup may be necessary.

- At 400 lbs, it’s relatively heavy, which could impact maneuverability and setup.

2. Boss 35 Ton H/V 3-Point Hitch Log Splitter

Specifications

- Splitting Force: 35 ton (dependent on tractor’s hydraulic output)

- Max Splitting Length: 25 inches

- Wedge Height: 8 inches

- Tractor Hydraulic Flow: 13-18 GPM recommended

- Tractor Hydraulic PSI: 2000-4000 recommended

- Cylinder Bore: 5 inches

- Operation: One-hand with auto-return

- Weight: 496 lbs (net) / 620 lbs (gross)

- Dimensions (LxWxH): 85×25.5×23.5 inches

- Warranty: 2-year residential, 180-day commercial

The Boss Industrial 35 Ton H/V 3-Point Hitch Log Splitter is a robust and versatile tool designed to harness the power of your tractor’s hydraulics for efficient wood splitting. With the ability to operate in both horizontal and vertical positions, this log splitter caters to a range of user preferences and log sizes.

This log splitter is capable of handling substantial wood splitting tasks, thanks to its impressive 35-ton maximum splitting force, which is, however, dependent on your tractor’s hydraulic output. It’s designed to connect seamlessly with both category 1 and category 2, 3-point hitches, making it adaptable to a broad spectrum of tractors. The convenience of switching between horizontal and vertical splitting positions, coupled with the adjustable working height, ensures comfort and efficiency during operation.

Pros

- With a potential 35-ton splitting force and the ability to work in both horizontal and vertical positions, this splitter is suitable for a wide array of wood splitting tasks.

- The working height is fully adjustable, ensuring you can work at a comfortable position, reducing strain and increasing productivity.

- A 2-year residential warranty, including hydraulics, provides peace of mind and reflects the manufacturer’s confidence in the product’s durability.

- With average split times ranging from 10-25 seconds, this splitter is designed for efficiency and speed.

- Fully adjustable for any category 1 or category 2, 3-point hitch size, enhancing its compatibility with various tractor models.

Cons

- The performance, including the tonnage and split times, is heavily dependent on the tractor’s hydraulic output, which may vary.

- Weighing 496 lbs (net), it’s relatively heavy, which might necessitate additional effort or machinery for positioning and setup.

- The need for a specific flow rate (10GPM minimum recommended) and PSI might limit its compatibility or performance with certain tractors.

3. Split-Fire 3403 3 Point Hitch Log Splitter

Specifications

- Frame: 6″ x 6″ steel tube

- Tonnage: 20 tons @ 2900 psi

- Cycle Speed: 9 sec. @ 12 gpm | 14 sec. @ 8 gpm | 28 sec. @ 4 gpm

- Power Source: 3 Pt. Hitch (tractor-powered)

- Stroke Length: 24″

- Bed Width: 15″

- Overall Dimensions (WxLxH): 34″ x 73″ x 18″

- Weight: 350 lbs

- Knife Height: 9½” (both 2-way and 4-way)

- Cylinder Size: 3½” x 24″

- Hydraulic Flow: 4 gpm – 12 gpm

- Warranty: 5 Years

The Split-Fire 3403 stands as a testament to Split Fire’s strong reputation in producing high-quality 3-point hitch log splitters. Renowned for its robust design, the 3403 model is part of a comprehensive range that promises to meet various firewood processing needs based on your tractor’s capabilities and your specific requirements.

The Split-Fire 3403 is engineered for efficiency and versatility, offering a robust 20-ton splitting force at 2900 PSI. It’s equipped with both 2-way and 4-way knives, making it capable of handling a diverse range of logs, from twisted tree line logs to those with straight grain. Distinguishing itself from conventional push-style log splitters, the 3403 features a quick, dual-action mechanism that significantly enhances both safety and productivity. Designed to accommodate logs up to 24 inches in length, it ensures broad usability for various splitting tasks. The splitter’s durability is reinforced through its robust frame and heavier log stops, promising longevity and steadfast performance in demanding conditions.

Pros

- The dual-action mechanism ensures quick and efficient wood splitting, maximizing productivity.

- With both 2-way and 4-way knives, the splitter can handle a wide range of log types and sizes, offering flexibility in operation.

- Since all fluid and power are sourced from the tractor, there’s no need for separate maintenance of the splitter, saving time and resources.

- The option to add weld-on features allows users to tailor the splitter to their specific needs, enhancing its utility.

- A 5-year warranty reflects the manufacturer’s confidence in the product’s durability and quality.

Cons

- Similar to other 3-point hitch log splitters, its performance relies on the tractor’s capabilities, which might vary.

- Users might need to purchase additional fittings for compatibility and ease of connection.

- The cycle speed is dependent on the hydraulic flow rate, which might require adjusting the tractor settings for optimal performance.

4. Rock Venom 25-Ton 3-Point Log Splitter

Specifications

- Base Dimensions (WxLxH): 700mm x 1400mm x 1150mm (H) / 1830mm (V)

- Overall Length: 1970mm

- Splitting Force: 25 tons

- Tractor Compatibility: Category 1 (CAT 1)

- Hitch: 3 Point

- Max Log Length: 22″

- Cycle Time: 11.5 – 15 sec

- Wedge: Hardened steel, 8″

- Max Pressure: 3200 psi

- Valve: Auto return

- Warranty: 3 years

The Rock Venom 25-Ton 3-Point Log Splitter is a heavy-duty machine designed for seamless integration with your tractor, promising power and efficiency in log splitting tasks. Recognized for its robust construction and user-friendly design, the Venom 25ton is geared towards those who need a reliable and powerful log splitting solution.

Constructed with a sturdy frame and equipped with a three-point linkage, the Rock Venom 25-Ton log splitter is easy to hitch to your tractor, ensuring you’re ready to split logs in no time. It offers the flexibility to work in both vertical and horizontal positions, catering to various log sizes and user preferences. The inclusion of a simple two-handled valve, compliant with EU health and safety regulations, ensures the operator’s safety is paramount. The addition of a small working table on the operator’s side is a thoughtful touch, keeping split logs conveniently at working height.

Pros

- A formidable 25-ton splitting force ensures it can handle a wide array of log sizes and types with ease.

- The ability to operate in both horizontal and vertical positions adds flexibility, accommodating different user needs and log dimensions.

- The inclusion of a two-handled valve, compliant with stringent safety standards, underscores the commitment to operator safety.

- The small working table on the operator’s side keeps split logs at a convenient working height, minimizing strain and enhancing efficiency.

- A 3-year warranty provides assurance about the splitter’s durability and quality.

Cons

- The splitter requires a minimum of 11GPM from the tractor to operate optimally, which might not be met by all tractors.

- Given its robust construction, the splitter might be relatively heavy and large, possibly requiring additional effort or machinery for positioning and setup.

Comparison Table of the Best 3-Point Hitch Log Splitters

| Feature / Model | RUGGEDSPLIT 322-24-TR | Boss 35 Ton H/V | Split-Fire 3403 | Rock Venom 25-Ton |

|---|---|---|---|---|

| Splitting Force | 22 tons | 35 tons | 20 tons | 25 tons |

| Operating Positions | Horizontal | Horizontal / Vertical | Horizontal / Vertical | Horizontal / Vertical |

| Cycle Time (Approx.) | Depends on tractor | 11 – 25 sec | 9 – 28 sec | 11.5 – 15 sec |

| Max Log Length | 24″ | 25″ | 24″ | 22″ |

| Hydraulic Flow Requirement | Not Specified | 10 – 18 GPM | 4 – 12 GPM | Min 11 GPM |

| Hitch Compatibility | Cat 1 or Cat 2 | Cat 1 or Cat 2 | Cat 1 or Cat 2 | Cat 1 |

| Weight | 400 lbs | 496 lbs | 350 lbs | Not Specified |

| Warranty | 1 year parts | 2 year residential, 180 day commercial | 5 years | 3 years |

Maintenance of 3-Point Hitch Log Splitter

- Regular Inspection: Conduct regular inspections of your 3-Point Hitch Log Splitter before and after each use. This should include a thorough check for any loose bolts, potential cracks in the welds, hydraulic leaks, or parts that show signs of wear. It’s crucial to ensure that all safety guards are securely in place and that warning labels are clear and legible. Additionally, inspect the hydraulic hoses for any signs of deterioration, such as wear, cracks, or leaks, and ensure that all hydraulic connections are securely tightened. Address any issues immediately to prevent further damage or potential safety hazards.

- Hydraulic System Maintenance: The hydraulic system is the heart of your log splitter, requiring meticulous care. Regularly monitor the level of hydraulic fluid and replenish it if necessary, adhering to the type recommended by the manufacturer. It’s essential to replace the hydraulic fluid and filter according to the maintenance schedule provided, typically annually or after a specified number of operation hours, to ensure the system remains contaminant-free. Regular inspections for any leaks in the hydraulic cylinders, valves, and pump are also crucial, as leaks can lead to reduced efficiency and pose safety risks.

- Wedge and Splitting Beam: Maintaining the wedge and splitting beam is vital for efficient operation. Keep the wedge sharp for easier and more efficient wood splitting. Inspect its condition regularly and sharpen it as needed, ensuring you follow the manufacturer’s safety guidelines meticulously. Post-operation, clean any wood debris off the splitting beam to ensure its smooth functioning and to minimize the risk of any wood pieces jamming the mechanism during subsequent uses.

- Greasing and Lubrication: Proper lubrication of moving parts is essential for smooth operation and longevity of your log splitter. Regularly apply grease to all grease fittings, pivot points, and other moving components to ensure smooth operation and to safeguard against rust and wear. Additionally, certain parts such as chains or gears may require specific lubrication – refer to the manufacturer’s instructions for the proper maintenance of these components.

- Safety Components: Safety should always be a top priority. Regularly verify that all safety components, including guards, shields, and emergency stop features, are in proper working condition. Operating the splitter with damaged or missing safety components can lead to severe accidents. Immediate attention to repairing or replacing these parts is imperative to ensure the safe operation of the machine.

- Storage: Proper storage of your log splitter is crucial for its preservation. When the splitter is not in use, store it in a dry, sheltered place to protect it from rust and weather-related damage. A protective cover can be beneficial to shield the splitter from dust and moisture, helping to maintain its condition and ensure it’s ready for use when needed.

- Seasonal Maintenance: At the start of each wood splitting season, it’s wise to perform a comprehensive check of the splitter’s components. If the splitter has been in storage for an extended period, it’s especially important to check all fluid levels, inspect for any signs of pest infestation or damage, and ensure the splitter is clean and completely dry before you begin operation.

Remember, while these guidelines provide a general framework for maintenance, you should always consult your specific model’s owner’s manual for the most accurate maintenance instructions and schedules. Regular and meticulous maintenance not only prolongs the lifespan of your log splitter but also ensures its safe and efficient operation.

Overall Conclusion

In conclusion, the log splitters we’ve explored – the RUGGEDSPLIT 322-24-TR, Boss 35 Ton H/V, Split-Fire 3403, and Rock Venom 25-Ton – each bring unique strengths to the table, catering to a variety of wood splitting needs. The RUGGEDSPLIT 322-24-TR impresses with its robust construction and versatile blade options, making it suitable for a wide range of tasks. The Boss 35 Ton H/V stands out with its powerful performance and the ability to operate in both horizontal and vertical positions, providing flexibility and efficiency. The Split-Fire 3403 distinguishes itself with a quick, dual-action mechanism and the capability to handle logs up to 24 inches, ensuring it’s not only efficient but also versatile in its operation. Lastly, the Rock Venom 25-Ton showcases its strength with a formidable 25-ton splitting force and user-friendly features, ensuring high productivity and safety.

All these models exhibit a blend of power, durability, and thoughtful design, making them top contenders in the realm of 3-Point Hitch Log Splitters. Whether you’re a professional seeking efficiency and power or a homeowner in need of a reliable tool for firewood preparation, these log splitters offer the performance and reliability to meet your needs. The choice ultimately depends on your specific requirements, including log size, tractor compatibility, and personal preferences in operation and handling.

Related Articles:

- Best Manual Log Splitters

- Best Log Splitter for the Money 2024

- 10 Best Log Splitters of 2023 Forestry Choices

FAQs

- What is a 3-Point Hitch Log Splitter and how does it differ from a standard log splitter?

A 3-Point Hitch Log Splitter is a type of log splitter that attaches to the three-point hitch of a tractor, utilizing the tractor’s hydraulic system for power. Unlike standalone log splitters, these do not have an independent engine and rely on the tractor for all their operational power, offering more strength and efficiency for heavy-duty tasks. - Can a 3-Point Hitch Log Splitter be used with any tractor?

Most 3-Point Hitch Log Splitters are compatible with Category 1 or Category 2 hitches, common in many tractors. However, it’s crucial to check the hydraulic flow requirements of the splitter and ensure your tractor can meet these specifications for optimal performance. - Is it possible to operate a 3-Point Hitch Log Splitter safely on uneven terrain?

Safety is paramount when operating any heavy machinery. While 3-Point Hitch Log Splitters can operate on slightly uneven terrain, it’s essential to ensure the stability of both the tractor and the splitter. Always refer to the manufacturer’s guidelines for specific safety instructions and terrain recommendations. - How does the splitting force of a 3-Point Hitch Log Splitter impact its performance?

The splitting force, measured in tons, directly impacts the splitter’s ability to handle logs of different sizes and wood types. Higher tonnage splitters can tackle larger, tougher logs, while lower tonnage models may be sufficient for smaller, softer wood. - Can I use a 3-Point Hitch Log Splitter for commercial purposes?

Yes, many 3-Point Hitch Log Splitters are robust enough for commercial use. It’s important to choose a model with the appropriate tonnage, cycle speed, and durability to meet the demands of commercial operations. - What maintenance is required for a 3-Point Hitch Log Splitter?

While the splitter itself may require minimal maintenance, such as checking connections and keeping components clean, it’s crucial to maintain the tractor’s hydraulic system regularly. Always refer to the owner’s manuals for both the tractor and the splitter for specific maintenance instructions. - How does the cycle time affect the efficiency of a 3-Point Hitch Log Splitter?

Cycle time, the duration it takes for the splitter’s ram to complete a full cycle (extend and retract), is crucial for efficiency. Shorter cycle times mean more logs can be split in less time, increasing productivity, especially in high-volume splitting tasks.

Dive into the conversation below by sharing your insights, experiences, or reviews of 3-Point Hitch Log Splitters. Your input is invaluable, helping others navigate their choices with greater assurance and knowledge. Whether you’re offering tips, recounting your personal experiences, or providing a detailed review, your contributions enrich our collective understanding. Let’s cultivate a supportive community where all log splitting aficionados can find guidance, exchange ideas, and enhance their wood processing journey together!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

Leave your comment