Weldcote Metals Ultraview Welding Helmet Review

- March 20, 2024

- 0 comment

The Weldcote Metals Ultraview welding helmet is a high-performing, true color technology helmet that enhances your welding experience with precision and comfort. It is equipped with features designed for both welding and non-welding applications, making it a versatile choice for professionals and hobbyists alike.

We’ve got your welding covered! Find comfy, Best welding gloves, Best welding carts, plus top picks for Best TIG Welder, Best MIG Welder & Best ARC Welders – all without breaking the bank!

Weldcote Metals Ultraview Specifications

- Brand Weldcote Metals

- True Color Technology Enhanced visibility and color accuracy.

- Shade Range 9-13 (welding), 5-9 (non-welding).

- Sensors 4 arc sensors for responsive shading.

- Power Solar charged, with CR2450 battery.

- Viewing Area 39% larger for improved visibility.

- Comfort Designed for prolonged use without discomfort.

- Warranty 3 years, including lens.

Key Features and Specifications

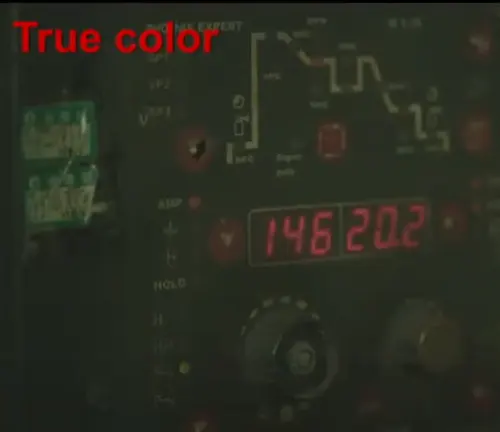

True Color Technology

Welding helmets, such as the Weldcote Metals Ultraview, revolutionizes how welders see their work by significantly enhancing visibility and color fidelity. This breakthrough ensures a crystal-clear and accurate view of the welding area and arc, thus enabling welders to perform their tasks with unprecedented precision and safety. The clarity provided by True Color Technology not only improves the quality of welds but also reduces eye strain, making the welding process more comfortable and efficient.

Versatile Shade Range

Shade range is designed to cater to a wide array of welding and grinding activities, ensuring both protection and clarity. With a shade range of 9-13 for welding tasks, it provides optimal darkness for arc welding processes. Conversely, for grinding and other non-welding tasks, a lighter shade range of 5-9 is available, offering sufficient protection while allowing more light for visibility. This adaptability enhances the helmet’s utility across different working conditions, making it a valuable tool for welders who engage in varied types of metalwork.

Comfort and Design

Designed with the wearer’s comfort and prolonged use in mind, featuring ergonomic adjustments and lightweight construction to prevent fatigue and discomfort. Its thoughtful design minimizes the risk of neck pain and strain, even after extended periods of continuous wear, making it an ideal choice for professional welders who spend long hours on their craft. This focus on comfort and user-friendly design ensures that welders can concentrate on their work with fewer distractions and discomforts, enhancing overall productivity and safety.

Digital Display

integrates a user-friendly digital display that streamlines the process of adjusting settings, enhancing the user experience by making it straightforward to modify parameters to fit specific welding requirements. However, it’s important to note that making these adjustments might necessitate temporarily removing the helmet, a minor inconvenience that is balanced by the precision and adaptability the digital controls provide. This feature ensures welders can easily tailor the helmet’s performance to their current task, promoting efficiency and optimal welding outcomes.

Ideal Users

The Weldcote Metals Ultraview helmet is well-suited for both seasoned welders and those new to the field. Its ease of use, durability, and functional design make it a beneficial tool for enhancing welding skills and ensuring safety during welding tasks.

For those in search of a welding helmet that combines high functionality with user comfort, the Weldcote Metals Ultraview presents a compelling option. Its true color technology, large viewing area, and versatile shade range cater to a broad range of welding and grinding applications, ensuring both safety and precision in your work

Weldcote Metals Ultraview Welding Helmet Pros and Cons

Pros

- True Color Technology offers clear, accurate views.

- Shade ranges for different tasks (9-13 welding, 5-9 non-welding).

- 4 arc sensors for reliable shading.

- Solar with CR2450 battery backup.

- Designed for extended wear without discomfort.

- 3 years, indicating durability.

Cons

- May require removal to adjust settings.

- Battery not included, adding to expenses.

Comparison Table with Other Models

| Feature | Weldcote Metals Ultraview | ESAB Savage A40 Air |

|---|---|---|

| Technology | True Color | True Color |

| Shade Range | 9-13 (welding), 5-9 (non-welding) | 9-13 |

| Arc Sensors | 4 | 4 |

| Power Supply | Solar and CR2450 battery | Solar cells and lithium batteries |

| Viewing Area | 39% larger than standard models | 100 x 50 mm (3.93 x 1.96 in.) |

| Weight | Not specified | Not specified |

| Comfort & Design | Designed for extended wear without discomfort | High tech lightweight shell |

| Adjustments | Digital display; some adjustments may require removal | Internal; sensitivity and delay adjustments |

| Grind Mode | Yes | Yes, with externally activated Grind Button |

| Respiratory Option | Not specified | Available with ESAB PAPR |

| Warranty | 3 years, including lens | Not specified |

ESAB Savage A40 Air Specifications

- Brand ESAB

- Technology ADF with True Color for enhanced vision.

- Shade Range DIN 9 to DIN 13, adjustable.

- Arc Sensors 4 sensors for improved response.

- Viewing Area 100 x 50 mm for broad vision.

- Power Solar cells and lithium batteries.

- Design Lightweight, protects against heat and spatter.

- Grind Mode External Grind Button, Shade 4.

- Adjustability Internal adjustments for delay and sensitivity.

- Respiratory Protection Compatible with ESAB PAPR.

- Optical Class 1/1/1/2 for excellent clarity.

Quantitative Measurements of Weldcote Metals Ultraview

- Shade Range 9-13 for welding, 5-9 for grinding and non-welding applications.

- Viewing Area The Ultraview model offers a 39% larger viewing area compared to standard models, though exact dimensions in square inches or millimeters were not specified.

- Number of Arc Sensors 4, for improved response to welding arc.

- Power Supply Solar panel with a backup CR2450 battery.

- Battery Type CR2450, replaceable.

- Switching Speed Typically measured in milliseconds (ms); however, the exact speed for the Ultraview was not specified. Welding helmets generally have a switching speed from light to dark of about 0.1 milliseconds.

- Weight Specific weight was not detailed, but modern welding helmets aim for lightweight design to reduce neck strain.

- Optical Class Not explicitly stated for Ultraview, but welding helmets often aim for a 1/1/1/1 rating, the best for clarity, light diffusion, variability, and angular dependence.

- UV/IR Protection: Provides up to DIN15, ensuring maximum protection against harmful radiation.

- Warranty Period: 3 years, including the lens, indicating confidence in durability and reliability.

Maintenance for Weldcote Metals Ultraview

- Regular Cleaning Wipe the helmet, especially the lens, with a soft cloth after each use to remove dust, dirt, and sweat which can accumulate and obscure vision.

- Lens Care Use a lens cleaner designed for welding helmets to clean the lens without scratching. Avoid harsh chemicals that can damage lens coatings.

- Inspect the Helmet Regularly check the helmet for any signs of damage, such as cracks in the shell or lens, which can compromise protection.

- Replace Damaged Parts If any part of the helmet is damaged, replace it immediately to maintain safety standards. This includes the lens, headgear, and any electronic components.

- Battery Check For models with a battery, regularly check and replace the batteries to ensure the auto-darkening feature works properly.

- Headgear Adjustment Adjust the headgear as needed for a secure and comfortable fit, which can shift over time with regular use.

- Arc Sensors Clean the arc sensors with a soft brush or cloth to ensure they continue to function correctly, detecting welding arcs to darken the lens automatically.

- Storage Store the helmet in a cool, dry place out of direct sunlight when not in use to prevent damage from heat and UV exposure.

- Avoid Impact Handle the helmet carefully to avoid drops or impacts that can crack the shell or damage internal components.

- Follow Manufacturer Guidelines Consult the helmet’s manual for specific maintenance recommendations from Weldcote Metals, including part replacement and technical support.

Safety Tips

- Proper Adjustment Before starting any welding project, ensure the helmet is properly adjusted to fit snugly and comfortably on your head. A well-fitted helmet provides maximum protection and prevents the helmet from shifting during welding, which could expose you to arc rays.

- Check Auto-Darkening Function Regularly test the auto-darkening feature of the helmet to ensure it’s functioning correctly. Exposure to sudden arc flashes with a non-functioning lens can cause “arc eye” or welder’s flash.

- Use Correct Shade Settings Adjust the lens shade according to the type of welding you’re performing. Using a shade that’s too light can lead to eye strain or damage, while a shade that’s too dark can impair visibility and increase the risk of welding defects or accidents.

- Maintain Clear Vision Keep the lens clean from smudges, dust, and spatter to maintain clear vision. Obstructed vision increases the risk of errors and accidents. Use appropriate cleaners that won’t damage the lens.

- Wear Additional PPE Even with a high-quality welding helmet like the Weldcote Metals Ultraview, it’s important to wear additional personal protective equipment (PPE) such as fire-resistant clothing, gloves, and safety shoes to protect against sparks, spatter, and UV radiation.

Conclusion

The Weldcote Metals Ultraview welding helmet exemplifies a perfect blend of technology, comfort, and utility, making it an excellent choice for welders at all levels of expertise. Its true color technology and expansive viewing area not only enhance visibility but also precision in welding tasks. The helmet’s solar-powered functionality, supplemented by a durable CR2450 battery, ensures reliable performance. Additionally, the comfort-focused design allows for extended use without the common discomfort associated with welding helmets. With a robust 3-year warranty, the Ultraview helmet stands as a testament to Weldcote Metals’ commitment to quality and user satisfaction, positioning it as a top choice for professionals and hobbyists seeking a high-performance welding helmet.

Frequently Asked Questions(FAQs)

- What technology does the Weldcote Metals Ultraview helmet use?

It utilizes True Color technology to improve visibility and color accuracy during welding operations. - Can I adjust the shade level on the Ultraview helmet?

Yes, the helmet offers adjustable shade levels from 9-13 for welding and 5-9 for non-welding applications, ensuring versatility across different tasks. - Is the Weldcote Metals Ultraview helmet battery-powered?

Yes, it features a solar-charged CR2450 battery to power the auto-darkening feature, providing long-lasting performance. - Does the Ultraview helmet come with a warranty?

Yes, it comes with a 3-year warranty, including the lens, which speaks to its durability and quality. - How many arc sensors does the Ultraview helmet have?

The helmet is equipped with 4 arc sensors for enhanced responsiveness and safety. - Can the Ultraview helmet be used for grinding?

Yes, it has settings suitable for grinding, offering versatility beyond welding. - What is the viewing area size of the Ultraview helmet?

The Ultraview helmet features a 39% larger viewing area compared to standard models, providing excellent visibility. - How do I maintain the Ultraview helmet?

Regular cleaning with appropriate cleaners, checking battery life, and storing it in a dry, safe place are key maintenance tips. - Is the Ultraview helmet comfortable for long periods of use?

Yes, it’s designed for comfort, minimizing neck strain and allowing for extended periods of use without discomfort. - Where can I purchase the Weldcote Metals Ultraview welding helmet?

It’s available through authorized Weldcote Metals distributors and various online retailers. Be sure to purchase from reputable sources to ensure authenticity and warranty coverage.

We’re eager to learn about your experiences with the Weldcote Metals Ultraview welding helmet! If you’ve used this helmet, please share your thoughts and feedback in the comments section below. Your personal insights and experiences could greatly assist fellow welders in making well-informed decisions about their protective gear. Whether it’s about the helmet’s comfort during long sessions, its true color technology, or any tips you have for maintaining it, your input is invaluable!

Jack Williams

Forestry AuthorI'm Jack Williams, Jack Williams, my expertise in welding and generator technologies extends beyond traditional boundaries. With over 13 years of experience, I have honed my skills in a range of heavy-duty equipment, focusing particularly on welding and power generation. My passion for nature and commitment to ecological sustainability inform my approach to work. I emphasize safety, efficiency, and staying current with technological advancements. Beyond my technical skills, I am dedicated to sharing knowledge and fostering environmental awareness, aiming to contribute positively to both the welding and generator operation industries.

Leave your comment