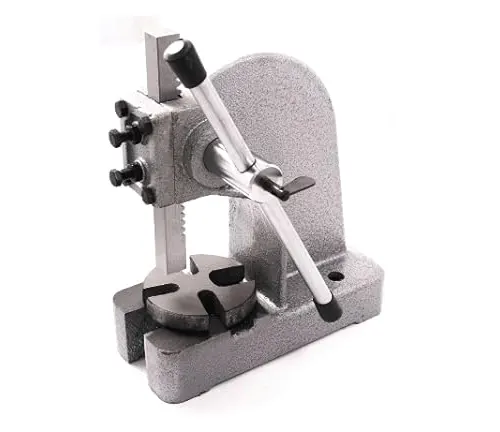

HHIP 8600-0033 Heavy Duty Arbor Press Review

- March 18, 2024

- 0 comment

Discover the prowess of the HHIP 8600-0033 Heavy Duty Arbor Press in our detailed review. This robust tool is engineered for a variety of pressing applications, excelling in workshops, factories, and machining environments with its heavy-duty construction and precision. Learn how it can transform your pressing operations with its significant force and reliability.

Specifications

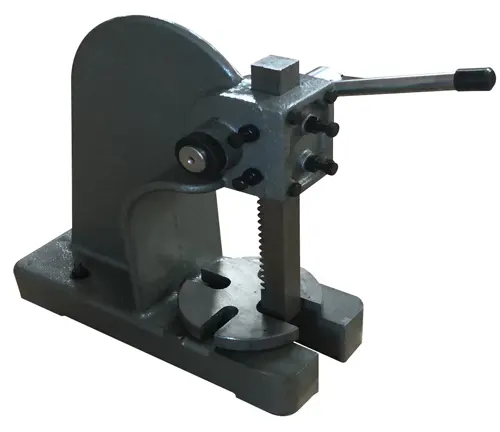

- Model: HHIP 8600-0033

- Type: Heavy-Duty Arbor Press

- Capacity: 2 Ton

- Height: 18 inches

- Product ID: 9841177

HHIP 8600-0033 Heavy Duty Arbor Press Review

Heavy-Duty Construction

The HHIP 8600-0033 Heavy Duty Arbor Press is constructed with exceptionally durable materials and reinforced components, engineered to withstand prolonged exposure to high pressure and frequent use. This robust construction ensures that the press maintains its structural integrity over time, providing reliable performance and longevity in industrial environments.

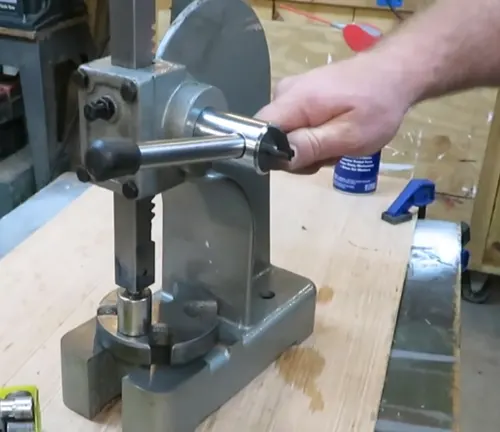

Adjustable Ram

The ram of the press is designed to be adjustable, allowing users to modify its height and position to accommodate various workpieces and pressing requirements. This flexibility enables precise customization for different tasks, enhancing the versatility of the arbor press and facilitating efficient operations across a wide range of applications.

Large Base

Equipped with a generously sized base, the arbor press offers ample stability and support during operation. The spacious base provides a solid foundation for the press, minimizing the risk of tipping or wobbling, even when exerting significant force. This stability enhances safety and accuracy, ensuring optimal performance in demanding pressing tasks.

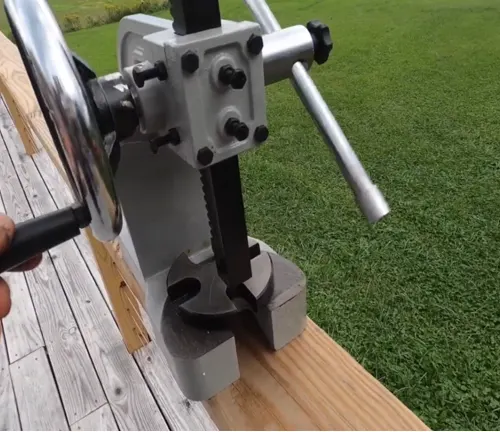

Hand-operated Lever

The arbor press is manually operated using a hand-operated lever mechanism, allowing operators to exert force with precision and control. By applying pressure to the lever, users can regulate the force applied to the workpiece, achieving accurate results according to specific requirements. This manual operation enables operators to maintain hands-on control over the pressing process, contributing to the precision and reliability of the arbor press.

Versatile Applications

The HHIP 8600-0033 Heavy Duty Arbor Press is capable of performing a wide range of pressing tasks, including assembling bearings, stamping, riveting, bending, and shaping metal or plastic parts. Its versatile design and adjustable features make it suitable for various industrial applications, offering flexibility and adaptability to meet diverse manufacturing needs.

Easy to Use

Despite its heavy-duty capabilities, the arbor press is designed for user-friendly operation, featuring intuitive controls and ergonomic design elements. The straightforward interface and ergonomic features ensure ease of use, allowing operators to work comfortably and efficiently without unnecessary complexity or difficulty. This user-centric design enhances productivity and reduces the learning curve, making the arbor press accessible to operators of all skill levels.

Reliable Performance

The HHIP 8600-0033 Heavy Duty Arbor Press consistently delivers superior performance, meeting the rigorous demands of industrial settings. Its durable construction, precise operation, and versatile capabilities make it a trusted choice for professionals seeking dependable results in pressing applications. Whether used for occasional tasks or continuous production,

HHIP 8600-0033 Heavy Duty Arbor Press: Pros and Cons

Pros

- Heavy-duty construction ensures durability and long-term reliability, making it suitable for demanding industrial applications.

- Adjustable ram allows for versatility in pressing operations, accommodating various workpieces and requirements.

- Large base provides stability during operation, reducing the risk of tipping or instability, and ensuring safety.

- Hand-operated lever enables precise control over the application of force, allowing for accurate results.

- Versatile applications make it suitable for a wide range of pressing tasks, enhancing its utility and versatility.

- Ease of use with intuitive controls and ergonomic design features contributes to user comfort and efficiency.

- Reliable performance ensures consistent results, making it a preferred choice in industrial settings.

Cons

- Manual operation may require physical effort, particularly for prolonged or repetitive tasks.

- Limited automation compared to hydraulic or pneumatic presses, potentially affecting productivity for high-volume production.

- Requires periodic maintenance and lubrication to ensure optimal performance and longevity.

- May have a higher initial cost compared to smaller or less robust arbor presses.

- Large footprint may require ample space in the workshop or production floor.

- Limited capacity for extremely heavy-duty pressing tasks compared to hydraulic presses.

- Depending on the application, manual operation may have limitations in terms of speed and precision compared to automated pressing systems.

HHIP 8600-0033 Heavy Duty Arbor Press: Comprehensive Analysis

| Pros | Cons | |

|---|---|---|

| Heavy-Duty Construction | – Ensures durability and long-term reliability. | – Manual operation may require physical effort. |

| Adjustable Ram | – Allows for versatility in pressing operations. | – Limited automation compared to hydraulic or pneumatic presses. |

| Large Base | – Provides stability during operation, ensuring safety. | – Requires periodic maintenance and lubrication. |

| Hand-operated Lever | – Enables precise control over the application of force. | – May have a higher initial cost compared to smaller arbor presses. |

| Versatile Applications | – Suitable for a wide range of pressing tasks. | – Large footprint may require ample space. |

| Ease of Use | – Intuitive controls and ergonomic design features enhance user comfort and efficiency. | – Limited capacity for extremely heavy-duty tasks compared to hydraulic presses. |

| Reliable Performance | – Consistent results make it a preferred choice in industrial settings. | – Manual operation may have limitations in terms of speed and precision. |

Conclusion

The HHIP 8600-0033 Heavy Duty Arbor Press stands out as a reliable and versatile tool for industrial pressing applications. Its robust construction, adjustable features, and ergonomic design ensure durability, flexibility, and ease of use. While manual operation may require physical effort and it may have limitations compared to automated systems, its consistent performance and wide range of applications make it a preferred choice for professionals seeking dependable results. With its combination of reliability, versatility, and user-friendly features, the HHIP 8600-0033 Heavy Duty Arbor Press proves to be a valuable asset in various industrial settings, delivering precise and efficient pressing operations.

Frequently Asked Questions (FAQs)

- What specific tasks can I perform with the HHIP 8600-0033 Heavy Duty Arbor Press?

- The HHIP 8600-0033 Heavy Duty Arbor Press is suitable for various tasks such as assembling bearings, stamping, riveting, bending, and shaping metal or plastic parts.

- What is the maximum force capacity of the HHIP 8600-0033 Heavy Duty Arbor Press?

- The HHIP 8600-0033 Heavy Duty Arbor Press can exert a maximum force capacity of [insert force capacity here, if available].

- How many height and position adjustments does the ram of the press allow?

- The ram of the press is adjustable and allows for multiple height and position adjustments to accommodate different workpieces and pressing requirements.

- Can you provide details about the materials used in the construction of the HHIP 8600-0033 Heavy Duty Arbor Press?

- The HHIP 8600-0033 Heavy Duty Arbor Press is constructed with durable materials such as [insert materials used, if available] to ensure longevity and reliability.

- What regular maintenance procedures are recommended for the HHIP 8600-0033 Heavy Duty Arbor Press?

- Regular maintenance procedures for the HHIP 8600-0033 Heavy Duty Arbor Press may include lubrication of moving parts, inspection of components for wear, and cleaning to remove debris or contaminants.

- Is the operation of the press entirely manual, or are there any automated features?

- Yes, the operation of the HHIP 8600-0033 Heavy Duty Arbor Press is entirely manual, utilizing a hand-operated lever mechanism for precise control over the application of force.

- Are there specific safety mechanisms or features integrated into the HHIP 8600-0033 Heavy Duty Arbor Press?

- The HHIP 8600-0033 Heavy Duty Arbor Press may include safety features such as safety guards or shields to protect operators from moving parts and pinch points.

- What is the warranty coverage for the HHIP 8600-0033 Heavy Duty Arbor Press, and what does it include?

- Warranty coverage for the HHIP 8600-0033 Heavy Duty Arbor Press varies depending on the manufacturer’s terms and conditions. Please refer to the product documentation or contact the manufacturer for specific warranty details.

- Are there any optional accessories or attachments available for the HHIP 8600-0033 Heavy Duty Arbor Press?

- Optional accessories or attachments for the HHIP 8600-0033 Heavy Duty Arbor Press may include additional tooling, specialized fixtures, or replacement parts. These accessories can enhance the functionality or adaptability of the press for specific applications.

- Can you provide the exact dimensions or footprint of the HHIP 8600-0033 Heavy Duty Arbor Press for space planning purposes?

- The exact dimensions or footprint of the HHIP 8600-0033 Heavy Duty Arbor Press can be provided by referring to the manufacturer’s specifications. These dimensions are essential for space planning and ensuring proper placement of the press in the workshop or production area.

Leave your comment