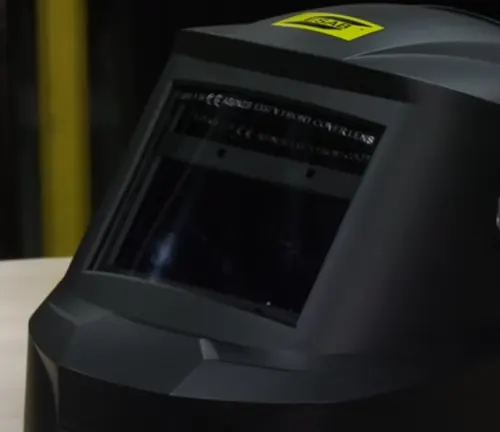

ESAB Savage A40 Air Welding Helmet Review

- March 20, 2024

- 0 comment

Discover the perfect blend of innovation and comfort with the ESAB Savage A40 Air Welding Helmet. Engineered for professional welders who demand both protection and performance, this helmet offers advanced auto-darkening technology, superior optical clarity, and enhanced safety features. Experience unmatched comfort and control in any welding environment, ensuring precision and efficiency in your work. The ESAB Savage A40 Air is more than just a welding helmet; it’s your trusted partner in achieving welding excellence.

We’ve got your welding covered! Find comfy, Best welding gloves, Best welding carts, plus top picks for Best TIG Welder, Best MIG Welder & Best ARC Welders – all without breaking the bank!

ESAB Savage A40 Air Specifications

- Brand ESAB

- Model Savage A40 Air

- Viewing Area Large

- Optical Clarity High

- Shade Levels Variable (5-8/9-13)

- Switching Speed Fast

- Weight Lightweight

- Power Solar cell & replaceable battery

- Features True Color, Grind Mode, Sensitivity and Delay Control

- Comfort Adjustable headgear

Design and Build Quality

The ESAB Savage A40 Air Welding Helmet boasts a robust and durable construction, which is essential for withstanding the rigors of welding environments.

The helmet features a sleek design with a large viewing area, providing welders with excellent visibility and comfort during prolonged use. The materials used in its construction are of high quality, ensuring longevity and reliability.

High-Definition Auto-Darkening Lens

Welding Helmet is equipped with a high-definition lens that employs advanced auto-darkening technology, ensuring welders experience crystal-clear visibility and seamless adaptation to changing light conditions. This feature allows for enhanced detail and accuracy, offering optimal protection while enabling precise work in a variety of welding environments.

Large Viewing Area

Large viewing area, providing welders with an unobstructed view of their workpiece and surrounding area, which is crucial for precision and safety during welding tasks. This expansive visibility not only improves control over welding operations but also significantly reduces the need for frequent helmet adjustments, allowing for a more efficient and comfortable welding experience.

Durable Construction

Designed with durability at its core, crafted to endure the rigorous and challenging conditions often found in welding environments. Its sturdy construction not only guarantees the helmet’s longevity but also ensures consistent reliability in protecting welders against the various hazards they face, providing peace of mind and a dependable performance over time.

Adjustable Headgear

Features adjustable headgear, engineered to accommodate a wide range of head sizes and shapes, ensuring a snug and secure fit for every user. This customization capability enhances comfort for welders, enabling them to work for extended periods without discomfort, thereby improving focus and efficiency on the task at hand.

Integrated Ventilation System

An integrated ventilation system that plays a crucial role in dissipating heat, ensuring that welders remain cool and comfortable even during intense welding sessions. This innovative feature also significantly reduces the risk of the lens fogging up, maintaining clear visibility and allowing for uninterrupted focus on welding tasks.

Intuitive Controls

Outfitted with intuitive controls, simplifying the process for welders to fine-tune settings like sensitivity and delay, tailoring the helmet to their specific needs and the demands of different welding projects. This ease of adjustment not only enhances welding performance but also ensures optimal eye protection by allowing for quick adaptation to varying light conditions and welding intensities.

Additional Features

- The helmet is equipped with intuitive controls, allowing welders to easily adjust settings such as sensitivity and delay according to their preferences and welding requirements.

- The helmet’s lightweight design reduces strain on the neck and shoulders, making it suitable for prolonged use without causing fatigue.

- The ESAB Savage A40 Air Welding Helmet meets industry standards for safety and protection, providing welders with peace of mind while working in hazardous environments.

ESAB Savage A40 Air Welding Helmet Pros and Cons

Pros

- The high-definition auto-darkening lens offers clear visibility.

- Adjustable headgear ensures comfort during prolonged use.

- Provides better control and visibility.

- Built to withstand harsh welding environments.

- Helps keep the welder cool and prevents lens fogging.

- Easy adjustment of settings for convenience.

- Reduces strain on the neck and shoulders.

- Meets industry standards for reliable protection.

Cons

- Higher cost may be a barrier for some buyers.

- Initial setup and adjustment might be challenging for some users.

- May require frequent replacement or recharging during heavy usage.

- Costly replacement if scratched or damaged.

- Not optimized for all specialized welding tasks.

Comparison Table with Other Models

| Feature | ESAB Savage A40 Air Welding Helmet | Optrel Crystal 2.0 |

|---|---|---|

| Viewing Area | Large (exact size may vary) | Large (100 x 50 mm) |

| Optical Clarity | Good (exact rating may vary) | 1/1/1/2 (exceptionally clear) |

| Weight | Lightweight (exact weight may vary) | Ultra-lightweight (460 g) |

| Shade Levels | Shades 5-8/9-13 (variable) | Crystal lens technology, shade level 2.0 in light state, 4 to 12 in dark state |

| True Color | Yes | Yes, Crystal lens technology for near-perfect color vision |

| Power Supply | Solar cell and replaceable battery | Solar cells and 2 CR2032 batteries |

| Sensitivity Control | Adjustable | Fully automatic adjustment |

| Delay Control | Yes | Yes |

| Grind Mode | Yes | Yes |

Optrel Crystal 2.0 Specifications

- Brand Optrel

- Weight 460g (Ultra-lightweight)

- Optical Clarity 1/1/1/2

- Viewing Area 100 x 50 mm

- Shade Range 2.0 in light state; 4-12 in dark state

- Power Solar cells with 2 CR2032 batteries

- Features True Color View, Autopilot shade level adjustment, Twilight Feature, Sensitivity adjustment for low amp TIG welding

- Grind Mode Yes

- Comfort Ergonomic design with adjustable headgear

- Accessories Magnifying lens compatible; optional respirator attachment

Quantitative Measurements of ESAB Savage A40 Air Welding Helmet

- Viewing Area Dimensions Typically, welding helmets have a viewing area measured in square inches or millimeters, indicating the size of the window through which the welder can see.

- Weight The weight of the helmet, often in pounds (lbs) or grams (g), affecting comfort and wearability for long periods.

- Shade Levels The range of shade levels the helmet can provide, crucial for protecting the welder’s eyes from the bright light of welding.

- Switching Speed The speed at which the helmet can switch from its light state to a dark state, usually measured in fractions of a second.

- Number of Sensors The quantity of sensors used to detect the welding arc, affecting the helmet’s responsiveness and reliability.

- Battery Type and Life Specifics about the battery, including type (e.g., lithium) and estimated life, important for maintenance and cost of ownership.

- Solar Panel Efficiency If applicable, the efficiency of the helmet’s solar panel, contributing to battery life and eco-friendliness.

- Minimum Operating Temperature The lowest temperature at which the helmet can operate effectively, important for working in cold environments.

- Maximum Operating Temperature Conversely, the highest temperature at which the helmet remains operational, critical for high-heat conditions.

- Adjustability Features Quantitative details on adjustability, such as the number of adjustments available for the headgear, to improve fit and comfort.

Maintenance for ESAB Savage A40 Air

- Regular Cleaning Clean the helmet’s exterior and viewing lens with a soft, lint-free cloth to remove dust and spatter. Avoid harsh chemicals that can damage the lens or helmet surface.

- Lens Inspection and Replacement Inspect the auto-darkening lens for scratches or cracks regularly. Replace it if any damage is found to ensure proper eye protection.

- Battery Check and Replacement Regularly check the battery’s charge level (if applicable) and replace it as needed to ensure the auto-darkening feature functions correctly.

- Headgear Adjustment Check the headgear’s fit and adjust it periodically to ensure the helmet remains secure and comfortable during use.

- Sweatband Maintenance If your helmet has a sweatband, clean or replace it regularly to maintain hygiene and comfort.

- Check Ventilation System For the Air version, ensure the air filtration and ventilation system is clean and unobstructed to maintain proper airflow.

- Filter Inspection Regularly inspect the air filter in the ventilation system (if applicable) and replace it according to the manufacturer’s recommendations.

- Software Updates If your helmet has any software or firmware, check for updates periodically to ensure optimal performance.

- Storage Store the helmet in a cool, dry place away from direct sunlight and extreme temperatures to prevent material degradation.

- Professional Inspection Consider having the helmet inspected by a professional periodically, especially the auto-darkening feature, to ensure it meets safety standards.

Safety Tips

- Proper Adjustment Before starting any welding task, ensure the helmet is properly adjusted to fit securely on your head. A well-fitted helmet provides better protection and prevents it from slipping or moving, which could expose your eyes or skin to harmful light or sparks.

- Regular Inspection Routinely inspect your helmet for any signs of wear, damage, or malfunction, especially the auto-darkening lens. Cracks, scratches, or a malfunctioning lens could compromise your safety, exposing you to dangerous light levels.

- Use With Appropriate PPE Always use your welding helmet in conjunction with other personal protective equipment (PPE), such as fire-resistant clothing, gloves, and safety shoes. Welding emits harmful UV rays, sparks, and spatter that can cause burns or other injuries.

- Understand Your Helmet’s Features Familiarize yourself with all the features and settings of your ESAB Savage A40 Air Welding Helmet, including the shade levels, sensitivity adjustments, and grind mode. Using the correct settings for your task is crucial for effective protection.

- Proper Ventilation When using the air-purifying feature of the ESAB Savage A40 Air, ensure that the ventilation system is correctly set up and functioning to avoid inhaling harmful fumes and gases. Always weld in a well-ventilated area or use appropriate respiratory protection if ventilation is inadequate.

Conclusion

In conclusion, the ESAB Savage A40 Air Welding Helmet is a top-of-the-line welding accessory that delivers exceptional performance, comfort, and safety. With its durable construction, advanced features, and user-friendly design, it’s a valuable asset for professional welders seeking reliability and precision in their work. Whether you’re a seasoned welder or a novice, investing in the ESAB Savage A40 Air is sure to enhance your welding experience and productivity.

Frequently Asked Questions(FAQs)

- What type of battery does the ESAB Savage A40 Air Welding Helmet use, and how often should it be replaced?

The helmet typically uses a standard CR2450 lithium battery. Replacement depends on usage but generally once every 1-2 years. - Can the ESAB Savage A40 Air Welding Helmet be used for all types of welding?

Yes, it’s suitable for TIG, MIG, and Stick welding, thanks to its variable shade levels and sensitivity settings. - How do I adjust the shade level on my ESAB Savage A40 Air Welding Helmet?

The shade level can be adjusted using the controls located on the outside of the helmet or inside the viewing area, depending on the model. - Is the helmet suitable for overhead welding?

Yes, it’s designed to protect against sparks and spatter from all welding positions, including overhead. - Can I wear prescription glasses while using this helmet?

Yes, the helmet’s design accommodates the use of prescription glasses underneath it. - How do I clean the viewing lens on my helmet?

Use a soft cloth and mild soap. Avoid abrasive materials or harsh chemicals that can scratch or damage the lens. - What is the viewing area size of the ESAB Savage A40 Air Welding Helmet?

The viewing area dimensions can vary; please refer to the specific model’s specifications for accurate measurements. - Does the helmet come with a warranty?

Yes, ESAB welding helmets typically come with a warranty. The duration and terms depend on the region and retailer, so it’s best to check with your supplier. - How do I know when to replace the filter lens on my welding helmet?

Replace the lens if you notice any cracks, scratches, or if the auto-darkening feature is not functioning properly. - Can the ESAB Savage A40 Air be used for grinding?

Yes, it has a grind mode setting that allows it to be used safely for grinding operations, protecting your eyes from sparks and debris.

We’re eager to hear from you! Share your personal experiences and insights about the ESAB Savage A40 Air Welding Helmet in the comments section below. Your feedback is invaluable, helping fellow welders make informed decisions. Whether it’s about its comfort, functionality, or any tips you’ve discovered, your contribution can make a difference!

Jack Williams

Forestry AuthorI'm Jack Williams, Jack Williams, my expertise in welding and generator technologies extends beyond traditional boundaries. With over 13 years of experience, I have honed my skills in a range of heavy-duty equipment, focusing particularly on welding and power generation. My passion for nature and commitment to ecological sustainability inform my approach to work. I emphasize safety, efficiency, and staying current with technological advancements. Beyond my technical skills, I am dedicated to sharing knowledge and fostering environmental awareness, aiming to contribute positively to both the welding and generator operation industries.

Leave your comment