Can You Cut PVC with a Miter Saw?

- April 22, 2024

- 0 comment

When tackling projects that involve PVC pipes, whether for plumbing, crafts, or construction, the question often arises: Can you cut PVC with a miter saw? The answer is a resounding yes, and doing so can be quite efficient, especially for those who need precise cuts or are working with large quantities of PVC.

Understanding the Tools and Techniques

When working on projects that require cutting PVC, understanding the right tools and techniques is crucial for achieving the best results.

Power Chop Saw/Miter Saw

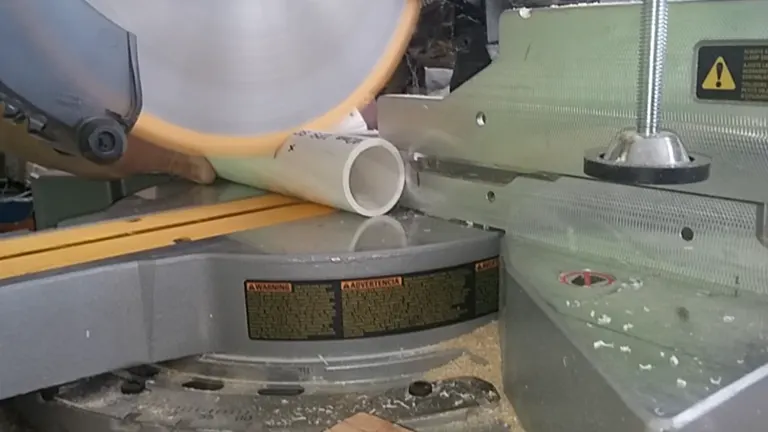

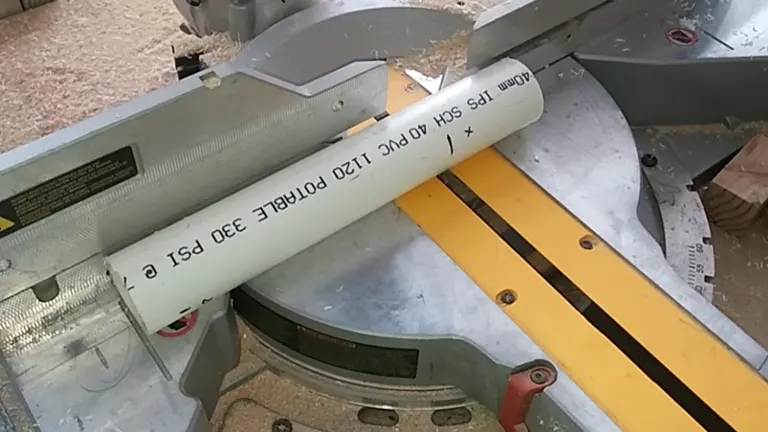

The power chop saw, also known as a miter saw, is highly recommended for cutting PVC due to its precision and efficiency. It allows you to make quick, clean cuts with minimal effort. The process involves marking your desired measurement on the PVC pipe, aligning it with the miter saw blade, and executing the cut. This method ensures a smooth, factory-like finish, ideal for projects requiring precise dimensions.

Alternative Methods

If a miter saw isn’t available, there are alternative tools you can use, such as:

- Sawzall with a Metal Cutting Blade: This tool is versatile and can handle cutting various materials, including PVC. While it may not provide as clean a cut as a miter saw, it’s effective for rougher cuts or when precision is less critical.

- Hacksaw: A traditional choice for manual cutting, a hacksaw offers simplicity and control. It requires more effort and may not yield as smooth a finish as a miter saw but is a good option for smaller or less frequent projects.

The Benefits of Using a Miter Saw for PVC

Using a miter saw for cutting PVC pipes comes with a host of benefits that can enhance both the efficiency and quality of your projects:

- Clean and Smooth Cuts: One of the main advantages of using a miter saw is its ability to produce clean and smooth cuts. The precision of the saw blade ensures cuts are burr-free, which minimizes the need for additional sanding or deburring. This clean cutting capability is particularly beneficial when preparing PVC pipes for a neat, professional finish in plumbing or construction projects.

- Efficiency: For projects involving multiple cuts or large quantities of PVC, a miter saw can save considerable time and effort. Unlike manual tools that require physical exertion and tend to be slower, a miter saw can rapidly handle cuts with a simple motion, making it ideal for larger scale projects or when time is of the essence.

- Precision: Precision is critical in many construction and plumbing tasks, and the miter saw excels in this area. It allows for exact measurements and makes consistent cuts, ensuring that each piece of PVC pipe fits perfectly with minimal adjustment. This level of precision is especially important in complex projects where accurate alignment affects the structural integrity or functionality of the installation.

Overall, incorporating a miter saw into your toolkit when working with PVC not only improves the quality of the cuts but also enhances the overall workflow by reducing labor and increasing the accuracy of each piece cut.

Considerations and Precautions

When using a miter saw to cut PVC pipes, there are several key considerations and safety precautions to keep in mind to ensure effective and safe operation:

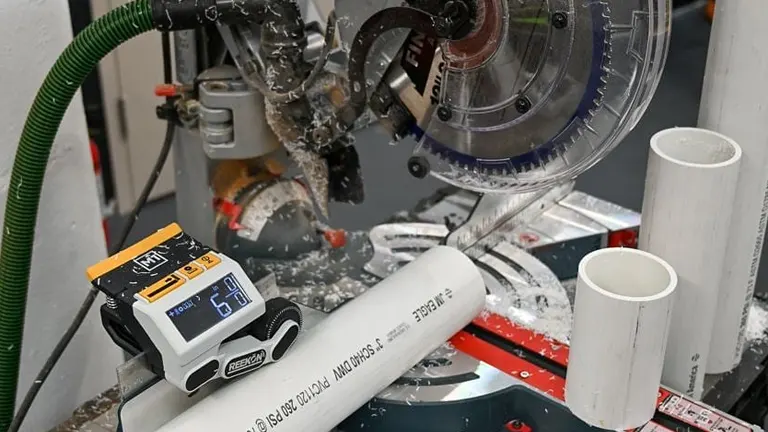

- Blade Type: Although a standard wood blade can be used to cut PVC, opting for a blade with finer teeth can enhance the cut quality. Finer-toothed blades help reduce chipping and melting along the cut edges of the PVC, resulting in a cleaner and more precise finish.

- Safety Precautions: It’s crucial to wear the appropriate safety equipment when operating a miter saw. Safety goggles protect your eyes from flying debris, and gloves can help guard against cuts and scrapes. Ensuring you have the right protective gear can significantly reduce the risk of injury. Before making a cut, make sure the PVC pipe is securely clamped or held in place. This prevents the pipe from moving or rotating during the cutting process, which not only ensures a straight cut but also reduces the likelihood of accidents.

- Heat Generation: Be mindful of how fast and how long you cut the PVC. High speeds and prolonged cutting can generate significant friction, which may heat the PVC to the point where it begins to melt. This melting can deform the cut edge, affecting the quality of the work and potentially causing inaccuracies in measurements or fittings. Adjusting the saw’s speed and taking breaks between cuts can help manage heat buildup and maintain the integrity of the PVC edges.

Practical Tips and Best Practices

- No Modifications Required: One of the advantages of using a miter saw for cutting PVC is that you don’t necessarily need a specialized blade. The typical wood blade that comes with your miter saw is generally sufficient for cutting PVC pipes. This not only simplifies the process but also saves on additional costs.

- Secure the Pipe: To achieve a clean and precise cut, it’s crucial to ensure that the PVC pipe is firmly secured before cutting. Movement during the cut can result in jagged or uneven edges, which could complicate further fittings or installations. Using clamps or a vise can help stabilize the pipe during the cutting process.

- Regular Blade Maintenance: Maintaining the sharpness and cleanliness of your saw blade is essential for consistent, quality cuts. A dull or dirty blade can cause tearing or melting of the PVC, leading to poor cut quality. Regularly cleaning the blade and sharpening or replacing it when necessary can extend the life of your miter saw and enhance cutting performance.

Personal Experience and Recommendations

Many users have successfully used miter saws to cut PVC without any issues, noting the efficiency and cleanliness of the cuts. It’s important, however, to avoid pushing the saw too quickly through the pipe, as this can cause the plastic to melt from the friction.

In conclusion, a miter saw can be a valuable tool for cutting PVC pipes, offering precision and efficiency. Whether you’re a DIY enthusiast or a professional, using a miter saw for your PVC cutting needs can save time and ensure high-quality results, making your project run smoother and faster.

FAQs

- Can you cut PVC with a miter saw?

Yes, a miter saw can be effectively used to cut PVC pipes, especially if equipped with a fine-toothed blade designed for plastic to ensure smooth cuts and minimize the risk of shattering or splitting the pipe. - What kind of blade is best for cutting PVC with a miter saw?

For cutting PVC, a blade with a higher tooth count is recommended, such as a crosscut blade with 60-80 teeth. This helps in making smoother cuts. Using a carbide-tipped blade is advantageous as it retains sharpness longer. - What are the benefits of using a miter saw to cut PVC pipes?

Using a miter saw for PVC pipes offers precision and clean cuts, saves time, and can handle various angles and sizes efficiently. It also minimizes the risk of damaging the PVC due to its controlled cutting environment. - What safety precautions should be taken when cutting PVC with a miter saw?

It’s crucial to wear eye protection to prevent debris from injuring your eyes. Ensure the work area is well-ventilated, especially to avoid inhaling any fumes from cutting. Secure the PVC pipe properly to prevent any movement during the cutting process. - Can a miter saw handle both wood and PVC?

Yes, with the right blade, a miter saw can efficiently cut both wood and PVC. Adjustments might be necessary, such as changing the blade or modifying the saw’s speed settings to accommodate the different materials. - Are there any specific adjustments to the saw when cutting PVC as opposed to wood?

When switching from wood to PVC, you may need to adjust the speed and blade type on your miter saw. Slower speeds and a finer-toothed blade help achieve a cleaner cut on PVC. - How do you prepare PVC pipes for cutting with a miter saw?

Measure and mark the pipe accurately where you want to cut. Secure the pipe firmly on a stable surface like a workbench with a vise to prevent any movement during cutting. This ensures a straight and precise cut. - Is it necessary to change the saw blade after cutting PVC?

Regularly inspect your blade after cutting PVC. If you frequently switch between materials, consider using a separate blade for PVC to maintain optimal cutting performance for each material type. - What should be considered before modifying a leaf blower’s tube?

Consider your specific needs for air speed versus volume and the material you’ll be clearing. Check the manufacturer’s guidelines to ensure that your modifications do not damage your blower or void its warranty. - How does changing the tube diameter affect leaf blower noise?

Reducing the tube diameter can increase the velocity and noise level of the blower, potentially requiring additional hearing protection during operation.

Do you have any thoughts or tips on cutting PVC with a miter saw? We’d love to hear how you tackle your projects! Drop a comment below to share your insights or questions with fellow DIY enthusiasts. Let’s learn and innovate together! Happy cutting!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

Leave your comment